Description

SuPAR, enables instant visual inspection of the physical objects in the quality control process, by superimposing its CAD model onto the object over real-time imagery from a device camera.

With the AR visualization SuPAR provides, visual inspection in the quality processes can be carried out much more efficiently and reliably.

SuPAR automatically creates a visual comparison of CAD data (how it should be) with what the camera sees (real situation). Thus, with the augmented reality (AR) technology, it is easily ensured that the targeted and real situations can be coincided and the deviations can be detected.

The software supports the user in three main tasks:

• Visual inspection/verification of various production tools, master models, sheet metal molds and parts, plastic parts, equipment and such series, prototypes and test parts,

• Recording problematic areas in notes and reports using annotations such as texts, photographs and 3D Notes, through created digital Twins,

• Communication through the created digital twin and video conference.

With SuPAR, parts of any size can be traced using a CAD file reference and can be checked in a very short time by a "Quality Assurer" without any calipers, templates, rulers, etc.

In addition, the virtual drawing tools and control notes offer the possibility of exporting outputs, such as notes and photos, overlapping of target and real situations, with an Excel file during and after the control. There is also a communication module where you can start a video conference.

SuPAR application areas can be various as follows.

• Dimensional quality control in the input and output processes of materials

• In the approval and acceptance of components and equipment,

• In the approval of the first sample shapes and geometries,

• Providing production standardization,

• In maintenance and repair processes, etc.

Using SuPAR saves great time and resources, helps achieve higher quality and process reliability with improved cognitive perception, simplifies the whole process and builds a better cooperation between operational processes.

In a nutshell, with the use of SuPAR;

• Quality issues are detected earlier with less effort and corrected easier and faster.

• All structural and geometric features are checked and documented.

Terms of Use: https://supar.eu/eula

Hide

Show More...

With the AR visualization SuPAR provides, visual inspection in the quality processes can be carried out much more efficiently and reliably.

SuPAR automatically creates a visual comparison of CAD data (how it should be) with what the camera sees (real situation). Thus, with the augmented reality (AR) technology, it is easily ensured that the targeted and real situations can be coincided and the deviations can be detected.

The software supports the user in three main tasks:

• Visual inspection/verification of various production tools, master models, sheet metal molds and parts, plastic parts, equipment and such series, prototypes and test parts,

• Recording problematic areas in notes and reports using annotations such as texts, photographs and 3D Notes, through created digital Twins,

• Communication through the created digital twin and video conference.

With SuPAR, parts of any size can be traced using a CAD file reference and can be checked in a very short time by a "Quality Assurer" without any calipers, templates, rulers, etc.

In addition, the virtual drawing tools and control notes offer the possibility of exporting outputs, such as notes and photos, overlapping of target and real situations, with an Excel file during and after the control. There is also a communication module where you can start a video conference.

SuPAR application areas can be various as follows.

• Dimensional quality control in the input and output processes of materials

• In the approval and acceptance of components and equipment,

• In the approval of the first sample shapes and geometries,

• Providing production standardization,

• In maintenance and repair processes, etc.

Using SuPAR saves great time and resources, helps achieve higher quality and process reliability with improved cognitive perception, simplifies the whole process and builds a better cooperation between operational processes.

In a nutshell, with the use of SuPAR;

• Quality issues are detected earlier with less effort and corrected easier and faster.

• All structural and geometric features are checked and documented.

Terms of Use: https://supar.eu/eula

Screenshots

SuPAR FAQ

-

Is SuPAR free?

Yes, SuPAR is completely free and it doesn't have any in-app purchases or subscriptions.

-

Is SuPAR legit?

Not enough reviews to make a reliable assessment. The app needs more user feedback.

Thanks for the vote -

How much does SuPAR cost?

SuPAR is free.

-

What is SuPAR revenue?

To get estimated revenue of SuPAR app and other AppStore insights you can sign up to AppTail Mobile Analytics Platform.

User Rating

App is not rated in Saudi Arabia yet.

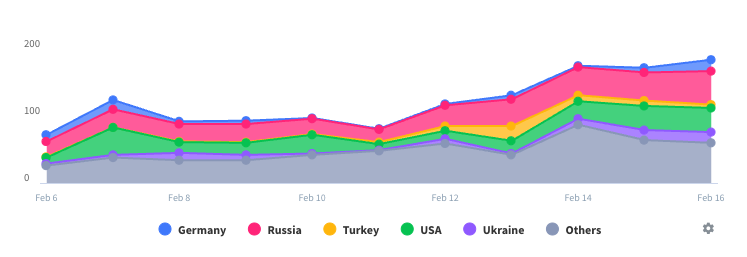

Ratings History

SuPAR Reviews

No Reviews in Saudi Arabia

App doesn't have any reviews in Saudi Arabia yet.

Store Rankings

Ranking History

App Ranking History not available yet

Category Rankings

App is not ranked yet

SuPAR Installs

Last 30 daysSuPAR Revenue

Last 30 daysSuPAR Revenue and Downloads

Gain valuable insights into SuPAR performance with our analytics.

Sign up now to access downloads, revenue, and more.

Sign up now to access downloads, revenue, and more.

App Info

- Category

- Business

- Publisher

- CDMVision

- Languages

- English

- Recent release

- 2023.2.100 (3 months ago )

- Released on

- May 4, 2021 (3 years ago )

- Also available in

- Türkiye, Germany, Japan, Hungary, United Kingdom, Romania, Czechia, Portugal, South Korea, Kazakhstan, Mexico, Malaysia, Netherlands, Norway, New Zealand, Peru, Pakistan, Poland, Israel, Saudi Arabia, Singapore, Thailand, Taiwan, Ukraine, United States, Vietnam, South Africa, Denmark, Argentina, Austria, Australia, Belgium, Brazil, Belarus, Canada, Switzerland, Chile, China, Italy, Algeria, Egypt, Spain, Finland, France, Greece, Hong Kong SAR China, Ireland, United Arab Emirates, India

- Last Updated

- 1 month ago