Downloads

Umsatz

Beschreibung

Inventory errors, stockouts and downtime are significantly reduced when using VMI Batch Order Entry. Vendors and suppliers that offer this inventory replenishment-based ordering system to their customer, either at that customer’s location or offsite, find that VMI Batch Order Entry is simple to use.

Using a handheld device, the VMI Batch Order Entry user (typically a representative of the vendor) will scan the items that their customer is running low on to bring that inventory back to pre-established levels. The user may also create additional orders to form a batch of orders that they will later upload to Latitude WMS once all quantities are reviewed and finalized. From there, the user posts the order(s) to the host system for creation, allocation, and shipper generation.

A warehouse employee working at the location that the replenishment items are being shipped from will pick, pack and ship the replenishment order to the customer. The customer will typically receive an advanced shipping notice they can then reference as soon as the shipment arrives and is ready to be received into inventory.

PathGuide now offers Advanced VMI which can run independently outside of the warehouse or as part of Latitude WMS. Orders are placed faster, easier and more efficiently than ever before – especially for customers who consistently order the same products. Features of Advanced VMI include customizable customer portals, bin-level management for complete inventory control, a self-service portal, lot and shelf-life management, serial number control management, consigned and non-consigned inventory management, ad-hoc replenishment, industrial vending machine support, SaaS-based multi-tenant cloud architecture, user-defined multilingual support, audit trails, compliance management, onboarding, project management, sourcing management, vendor master data management, collaboration, transaction history, and performance metrics.

Ausblenden

Mehr anzeigen...

Using a handheld device, the VMI Batch Order Entry user (typically a representative of the vendor) will scan the items that their customer is running low on to bring that inventory back to pre-established levels. The user may also create additional orders to form a batch of orders that they will later upload to Latitude WMS once all quantities are reviewed and finalized. From there, the user posts the order(s) to the host system for creation, allocation, and shipper generation.

A warehouse employee working at the location that the replenishment items are being shipped from will pick, pack and ship the replenishment order to the customer. The customer will typically receive an advanced shipping notice they can then reference as soon as the shipment arrives and is ready to be received into inventory.

PathGuide now offers Advanced VMI which can run independently outside of the warehouse or as part of Latitude WMS. Orders are placed faster, easier and more efficiently than ever before – especially for customers who consistently order the same products. Features of Advanced VMI include customizable customer portals, bin-level management for complete inventory control, a self-service portal, lot and shelf-life management, serial number control management, consigned and non-consigned inventory management, ad-hoc replenishment, industrial vending machine support, SaaS-based multi-tenant cloud architecture, user-defined multilingual support, audit trails, compliance management, onboarding, project management, sourcing management, vendor master data management, collaboration, transaction history, and performance metrics.

Screenshots

Latitude VMI Häufige Fragen

-

Ist Latitude VMI kostenlos?

Ja, Latitude VMI ist komplett kostenlos und enthält keine In-App-Käufe oder Abonnements.

-

Ist Latitude VMI seriös?

Nicht genügend Bewertungen, um eine zuverlässige Einschätzung vorzunehmen. Die App benötigt mehr Nutzerfeedback.

Danke für die Stimme -

Wie viel kostet Latitude VMI?

Latitude VMI ist kostenlos.

-

Wie hoch ist der Umsatz von Latitude VMI?

Um geschätzte Einnahmen der Latitude VMI-App und weitere AppStore-Einblicke zu erhalten, können Sie sich bei der AppTail Mobile Analytics Platform anmelden.

Benutzerbewertung

Die App ist in Neuseeland noch nicht bewertet.

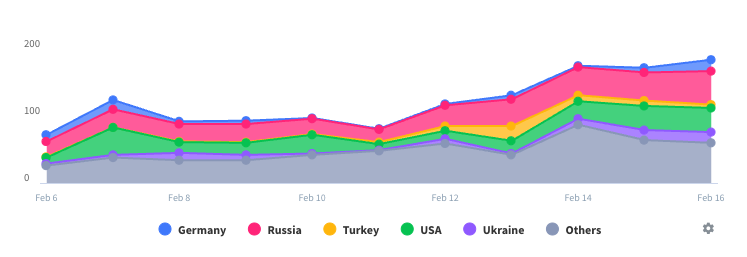

Bewertungsverlauf

Latitude VMI Bewertungen

Keine Bewertungen in Neuseeland

Die App hat noch keine Bewertungen in Neuseeland.

Store-Rankings

Ranking-Verlauf

App-Ranking-Verlauf noch nicht verfügbar

Kategorien-Rankings

App ist noch nicht gerankt

Latitude VMI Installationen

Letzte 30 TageLatitude VMI Umsatz

Letzte 30 TageLatitude VMI Einnahmen und Downloads

Gewinnen Sie wertvolle Einblicke in die Leistung von Latitude VMI mit unserer Analytik.

Melden Sie sich jetzt an, um Zugriff auf Downloads, Einnahmen und mehr zu erhalten.

Melden Sie sich jetzt an, um Zugriff auf Downloads, Einnahmen und mehr zu erhalten.

App-Informationen

- Kategorie

- Productivity

- Herausgeber

- PathGuide Technologies

- Sprachen

- Letzte Veröffentlichung

- 1.18 (vor 1 Jahr )

- Veröffentlicht am

- Jan 15, 2021 (vor 3 Jahren )

- Auch verfügbar in

- Italien, Südafrika, Vereinigte Staaten, Türkei, Thailand, Schweden, Russland, Neuseeland, Norwegen, Niederlande, Kuwait, Argentinien, Irland, Indonesien, Griechenland, Frankreich, Ägypten, Dominikanische Republik, Deutschland, Kanada, Australien, Österreich

- Zuletzt aktualisiert

- vor 3 Wochen

This page includes copyrighted content from third parties, shared solely for commentary and research in accordance with fair use under applicable copyright laws. All trademarks, including product, service, and company names or logos, remain the property of their respective owners. Their use here falls under nominative fair use as outlined by trademark laws and does not suggest any affiliation with or endorsement by the trademark holders.

- © 2024 AppTail.

- Unterstützung

- Privacy

- Terms

- All Apps